-

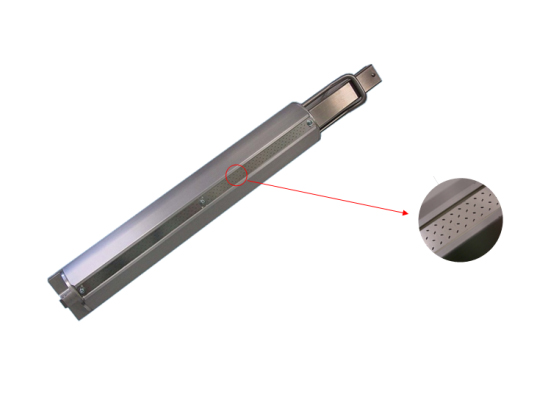

IonGun

Features- Particle-Free Ionization

- No Particle Generation from Ion Emitter

- Internal Cylindrical ULPA Filter Removes Particles from Air Supply

- No Over-Charging

- Zero Ozone Generation

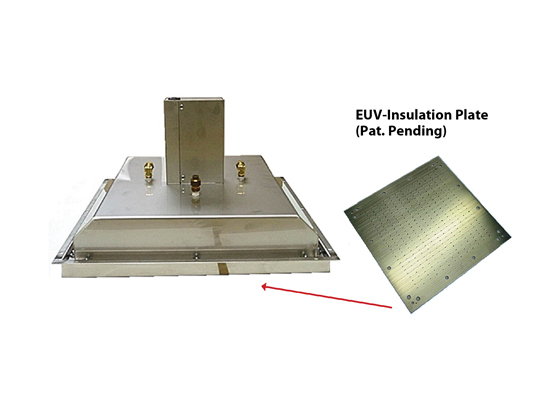

- EUV-Insulation Plate Prevents EUV Leakage

- Dedicated Radiation Zones / Personnel Not Required

- High Frequency Noise Mitigation Not Required

- Maintenance: Annual EUV Tube Replacement Only

-

IonGun

Features- Particle-Free Ionization

- No Particle Generation from Ion Emitter

- Internal Cylindrical ULPA Filter Removes Particles from Air Supply

- No Over-Charging

- Zero Ozone Generation

- EUV-Insulation Plate Prevents EUV Leakage

- Dedicated Radiation Zones / Personnel Not Required

- High Frequency Noise Mitigation Not Required

- Maintenance: Annual EUV Tube Replacement Only

-

IonGun

Features- Particle-Free Ionization

- No Particle Generation from Ion Emitter

- Internal Cylindrical ULPA Filter Removes Particles from Air Supply

- No Over-Charging

- Zero Ozone Generation

- EUV-Insulation Plate Prevents EUV Leakage

- Dedicated Radiation Zones / Personnel Not Required

- High Frequency Noise Mitigation Not Required

- Maintenance: Annual EUV Tube Replacement Only

-

Fluxless Reflow Oven

With traditional processes there are three types of processes needed to carry out fluxless reflow processes, a flux coating machine, reflow machine, and flux cleaning machine. The fluxless reflow oven from RORZE can perform all of these functions in one machine.

This also removes the existence of voids, reduces investment and running costs, as well as reduces the negative effects on the environment. All in all this machine can save you time and money but improving the efficiency of your operations and lowering the footprint of your machinery.- Fully-auto operation

- Single wafer process

- 200mm/300mm

- Recipe controlled forming gas in/out

Home

Home